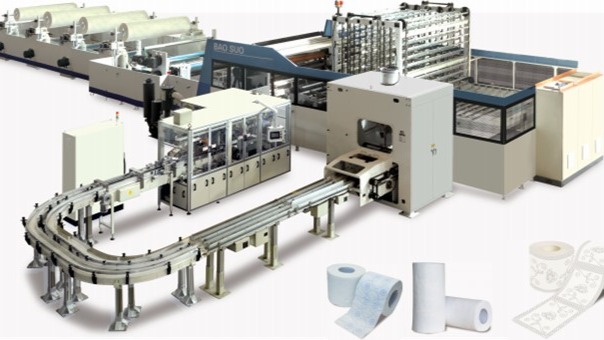

Trl-Pl450C Non-Stop Toilet Roll&Kitchen Towel Rewinding Line

Toilet Paper production Machines

Main Technical Parameters

- Design Speed: Specify Design Speed

- Jumbo Roll Width: 1750~3600 Mm

- With Core Speed: 450 m/Min

- Coreless Speed: 250 m/Min

- Jumbo Roll Diameter:1500 Mm To 2000 Mm

- Core Size Of Jumbo Roll: Φ76.2 Mm (Other Sizes Available)

- Diameter Of Finished Log: Φ60-130 Mm

- Core Size: Φ35-50 Mm

- Parameter Setup: Large Screen Hmi

- Control System: Plc

- Tension System: Encoder, Plc, Inverter

Optional:

- Embossing Unit (1-3 Ply, Independent Drive), Edge Embossing Unit (Steel-To-Steel), Printing Unit (1-2 Colors, Customer Provides Pattern)

Accumulator

- Diameter Of Log: Φ70-135 Mm

- Storage Capacity: 160 Logs (Other Sizes Available Upon Request)

- Storage Speed: 25 Logs/Min

Glue-Free Embossing And Lamination Unit (El350)

- Production Speed: 300 m/Min

- Automatic Cleaning Device: Independent Motor-Driven Roller Brush To Clean Dust From The Embosser Roll

- Doctor Blade: Cleans Dust From The Steel Roll

- Embossing Depth Adjustment: Cylinder-Loaded Pressure With Precise Thread Adjustment For Easy Control

- Web Break Detection: Includes New Paper Detection System

- Tension Control: Manages Web Tightness

Log Saw (Ls160-2L/3L/4L)

- Log Convey System: Servo Motor System For Accurate Log Positioning

- Design Speed: 160 Cuts/Min

- Number Of Lines: 2-4 Lines

- Grinding System: Pneumatic Sharpening With Adjustable Parameters Via Touch Panel

- Cutting Tolerance: Precision Adjustment

- Clamp Size: Standard Size Is 110 Mm, Adaptable To Log Diameter Φ70-135 Mm

- Suction Dust System: Removes Dust From Grinding Wheel To Prevent Blackening

- Cooling System: Compressed Air Cooling For Grinding Knife

Related Products.